Hook cylinder, as a special design of pneumatic components, its model naming and learning points involved in a number of aspects.

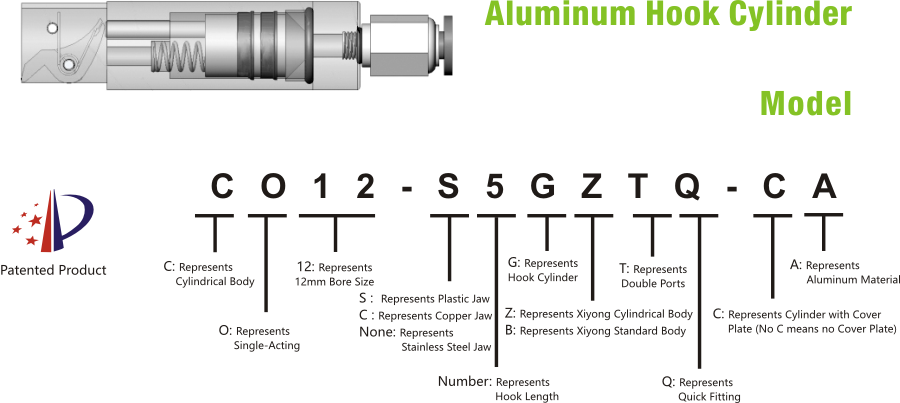

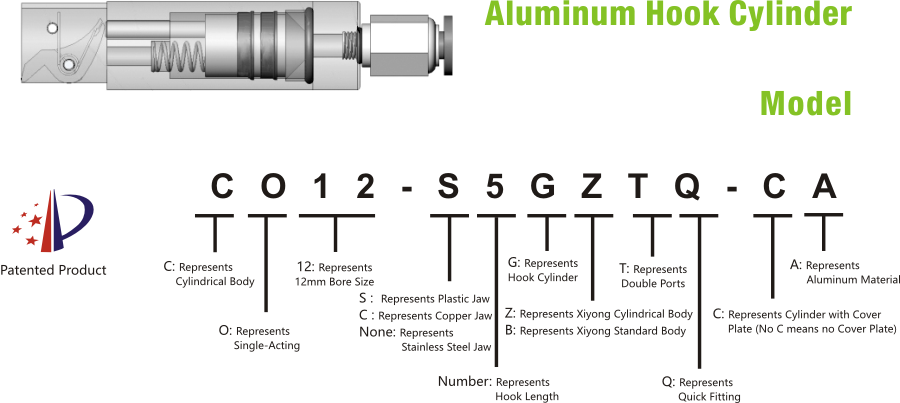

Ⅰ. Model Naming Rules

Hook cylinder model naming usually follow certain rules, these rules may vary from manufacturer to manufacturer, but in general contains the key features and design parameters of the cylinder. Generally speaking, model naming may contain the following parts:

1. Type identification: such as “G” for hook, “D” for side push cylinder, etc., this part is used to distinguish the type of cylinder.

2. Series or model number: used to identify the specific model or series of cylinders, this part is usually a combination of letters and numbers, the specific meaning needs to be determined according to the manufacturer's naming rules.

3. Dimensional parameters: may include the cylinder bore, stroke and other key dimensional information, this information is usually expressed in numerical form, and may contain specific units (such as millimeters).

4. Function or feature description: Some model designation may contain a short description of the function or feature of the cylinder, such as “cushioning”, “corrosion resistance”, “welding”, etc., to help users quickly understand the additional features of the cylinder. Quickly understand the additional characteristics of the cylinder.

5. Material: In general, the cylinder is divided into aluminum (A) and plastic (P).

Ⅱ. Learning Points

Understand the naming rules: Familiarize yourself with the naming rules of different manufacturers, which will help you quickly understand the meaning represented by each part of the model.

Master the key parameters: the cylinder bore, stroke and other key parameters directly affect its performance and scope of use. When learning the model, pay special attention to the meaning and value range of these parameters.

Understand the functional characteristics: different models of hook cylinders may have different functional characteristics, such as cushioning, corrosion resistance, high precision and so on. Understanding these characteristics will help you choose the right model according to actual needs.

Check the relevant information: Manufacturers usually provide detailed product manuals or selection guides, which contain detailed parameters, performance curves, mounting dimensions and other information about the cylinders. When learning the model, make full use of these materials to deepen the understanding and knowledge of the cylinder.

Practical application: Deepen the understanding of hook cylinder models through practical application. In the actual project, according to the working conditions and needs to choose the right model, and observe its performance in the actual operation, helps to better grasp the characteristics of the cylinder and the use of methods.

Ⅲ. Specific Model Examples

Take the hook cylinder of Xiyong Hardware & Electrical as an example, its model number may be named as “CO12-5GZ-A”, where:

“C” stands for round cylinder.

“O” stands for single cylinder.

“12” stands for 10mm cylinder bore.

“5” stands for hook length.

“G” stands for hook cylinder.

“Z” stands for straight barrel cylinder.

“A” stands for aluminum.

The model naming and learning points of hook cylinder involve many aspects, including naming rules, key parameters, functional characteristics and so on. When learning, it is necessary to be familiar with the naming rules of different manufacturers, master the meaning and value range of key parameters, understand the functional characteristics of the cylinder, and make full use of relevant information and practical applications to deepen the understanding and knowledge of the cylinder.

Prev:Round Cylinder VS Square Cylinder

Next:Popular knowledge of solenoid valve: reveal its working principle, classification and application scenarios