Solenoid valve, as the use of electromagnetic principle of precise control of fluid flow of mechatronics core components, in the modern industrial automation control field occupies a pivotal position. According to the different design of its control path, the solenoid valve is mainly divided into two-position and three-position categories, each category carries a specific function and application scenarios.

1. Definition and classification

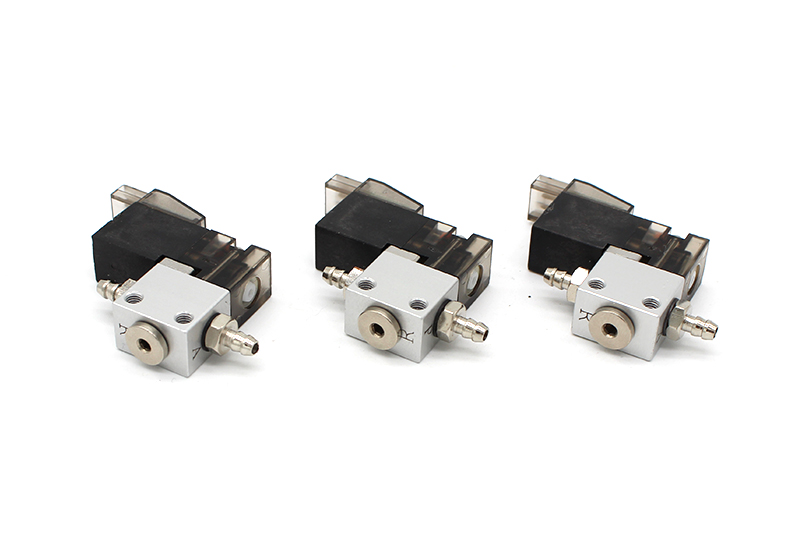

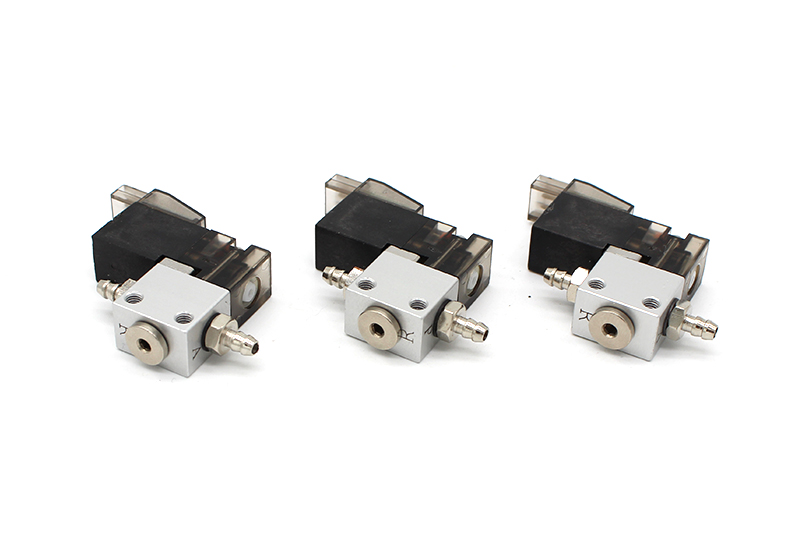

Solenoid valve, through the electromagnetic force to drive the spool movement, so as to realize the precise control of the fluid (including gas and liquid) flow state. In the classification, according to the number of spool working position, solenoid valve is clearly distinguished as two-position and three-position two major types. Among them, the word “position” refers to the steady state position of the spool, while “through” refers to the number of fluid passages. For example, a 2-position 3-way solenoid valve has two steady state positions (open and closed) and three fluid passages (inlet, outlet and exhaust), while a 2-position 5-way solenoid valve further expands the passage configuration on this basis, enhancing the flexibility of fluid control.

2. Structural characteristics

Examined from the perspective of structural design, two-position solenoid valve is known for its simple and clear structure, contains only open and close two steady state position, through the solenoid's suction and release to realize the valve's rapid switching, suitable for the basic on and off control of the fluid. In contrast, the three-position solenoid valve is the introduction of a more complex structural design, adding a third steady state position - the reverse path, so that the fluid can be freely switched between different outlets, while retaining the closed state, for the control system to provide a richer fluid control strategy and higher accuracy.

3. The working principle analysis

At the working principle level, two-position solenoid valve by controlling the presence or absence of current to affect the magnetization state of the solenoid, and then drive the spool in the open and closed position switching, to achieve precise control of the fluid path. The three-position solenoid valve is based on the integration of a more complex control logic, by changing the solenoid excitation, so that the spool can move to the third position, to achieve the reversal of the fluid flow or shunt, some high-end models even have a flow adjustment function, according to the actual demand for precise control of the fluid flow size.

4. Application

Two-position solenoid valve because of its simple structure, high reliability, cost-effective and other characteristics, in agricultural irrigation, horticultural spraying, water treatment, air pressure regulation and many other areas have been widely used in these industries to realize the automation control of an important tool. And three solenoid valves with its powerful direction control and flow regulation capabilities, in food processing, medical and pharmaceutical, petrochemical, environmental protection and other more stringent fluid control requirements of the industry to show excellent performance.

In summary, the solenoid valve as a core component in the field of industrial automation control, its two and three categories have their own characteristics, widely used in different industries and fields. In the selection and application process, according to the actual demand, media characteristics and use of the environment and other factors for comprehensive consideration to ensure that the solenoid valve can give full play to its performance advantages, industrial automation and intelligent process to provide solid support.

Prev:What should be noted when choosing a side push cylinder?

Next:How to choose cylinders for your harness test bench