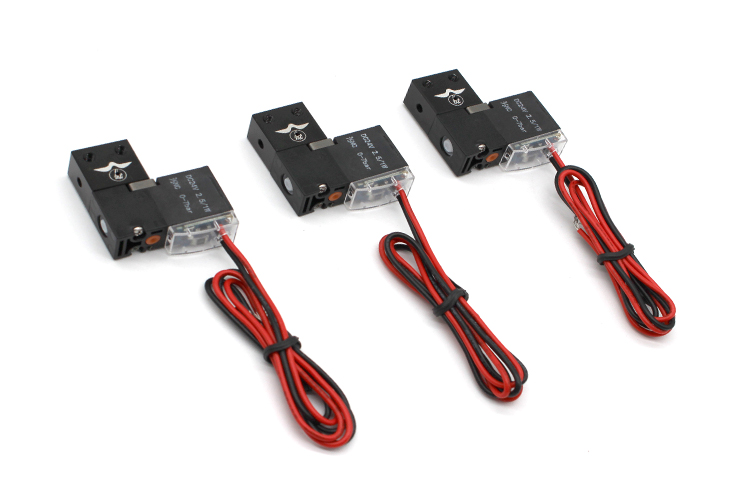

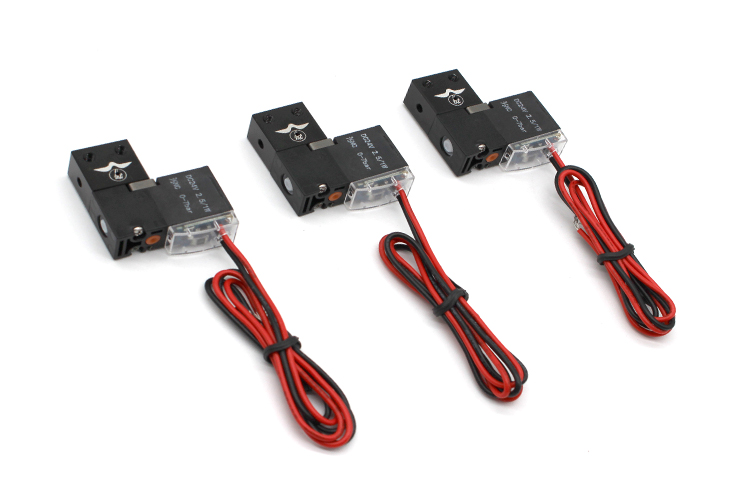

Electromagnetic valve is a commonly used automation control component, which has a wide range of applications in industrial production, daily life and many other fields. The following is an introduction to its working principle and importance:

Working principle

The basic working principle of solenoid valves is to use electromagnetic force to control the opening and closing of valves, thereby achieving on/off control of fluids (such as gases and liquids).

It is mainly composed of electromagnetic coils, valve cores, valve seats and other components. When the electromagnetic coil is energized, it generates a magnetic field, which causes the valve core to overcome resistance such as spring force and produce displacement, thereby opening or closing the valve channel. For example, in a normally closed solenoid valve, the valve core tightly adheres to the valve seat under the action of a spring before being energized, and the valve is in a closed state, preventing fluid from passing through; After being powered on, the electromagnetic force attracts the valve core to move upward, leaving the valve seat, and the valve opens, allowing fluid to pass smoothly. On the other hand, normally open solenoid valves are the opposite, with the valve closed when powered on and open when powered off.

According to their different structures and working modes, solenoid valves are mainly divided into three types: direct acting, step-by-step direct acting, and pilot operated.

1. Direct acting solenoid valve

Principle: When the electromagnetic coil is energized, it generates electromagnetic force to lift the valve core from the valve seat and open the valve; When the power is cut off, the electromagnetic force disappears, and the spring presses the valve core back to the valve seat, causing the valve to close.

Features: Suitable for low-pressure and low flow situations, able to work normally under vacuum, negative pressure or zero pressure.

2. Step by step direct acting solenoid valve

Principle: Combining the principles of direct acting and pilot operated. When there is no pressure difference, the electromagnetic force directly lifts the pilot small valve and the main valve closing member; When a certain pressure difference is reached, the main valve core is driven by fluid pressure.

Features: Suitable for situations with zero or high pressure difference, but with high power, it usually requires horizontal installation.

3. Pilot operated solenoid valve

Principle: When powered on, electromagnetic force opens the pilot hole, creating a pressure difference between the upper and lower chambers of the main valve. Fluid pressure pushes the main valve core upward, and the valve opens; When the power is cut off, the spring force or fluid pressure causes the main valve core to close.

Features: Suitable for high-pressure, high flow applications, small size, low power.

importance

Accurate control: It can achieve precise control of fluids and adjust parameters such as flow rate, pressure, and flow direction accurately according to different work requirements. For example, in industrial automation production lines, the supply of liquids or gases can be precisely controlled through solenoid valves, ensuring the stability of the production process and the consistency of product quality.

Automated operation: It is easy to achieve automated control and can be integrated with various automation control systems, such as PLC (Programmable Logic Controller), DCS (Distributed Control System), etc. In industrial production, these control systems can remotely control the opening and closing of solenoid valves, achieving automated operation of the process flow, greatly improving production efficiency, reducing labor costs, and minimizing human interference in the production process.

Security assurance: plays a role in security protection in many systems. For example, in a gas supply system, when abnormal situations are detected (such as gas leaks, abnormal pressure, etc.), solenoid valves can quickly cut off the gas supply, prevent accidents, and ensure the safety of personnel and equipment. In the fire protection system, solenoid valves can be used to control the supply of fire water. When a fire occurs, the valve automatically opens to ensure that fire water can be sprayed to the fire scene in a timely manner.

Wide applicability: Suitable for various working media and environments. Whether in special environments such as high temperature, low temperature, high pressure, low pressure, or for fluids of different properties (such as corrosive liquids, viscous fluids, etc.), suitable materials and structures of solenoid valves can be selected to meet the working requirements. This has led to the widespread application of solenoid valves in many industries such as chemical, petroleum, pharmaceutical, food and beverage.

3、 Application scenarios of solenoid valves

Electromagnetic valves have a wide range of applications, in addition to industrial, civilian, and automotive fields, they also have important applications in the following areas:

Medical field

Medical devices: such as medical ventilators, solenoid valves are used to precisely control the flow and pressure of gases, providing patients with appropriate respiratory support. In the anesthesia machine, solenoid valves can control the delivery of anesthesia gas, ensuring the safety and accuracy of the anesthesia process.

Medical equipment: In some medical testing equipment, such as blood analyzers, urine analyzers, etc., solenoid valves are used to control the delivery of samples and reagents, ensuring the accuracy and reliability of the testing process.

aerospace field

Aircraft engine: used to control the delivery and regulation of fluids such as fuel, lubricating oil, and hydraulic oil, ensuring that the engine can operate normally under various flight conditions. For example, precise control of fuel supply enables the engine to maintain optimal combustion conditions at different flight altitudes, speeds, and loads, improving engine performance and efficiency.

Aircraft hydraulic system: Electromagnetic valves play a critical control role in hydraulic systems such as landing gear retraction and flight control surfaces. It can quickly and accurately control the flow and pressure of hydraulic oil, achieve reliable retraction and precise control of landing gear and flight control surfaces, and ensure flight safety.

agriculture

Irrigation system: In agricultural irrigation, solenoid valves are widely used in drip irrigation, sprinkler irrigation and other systems. By cooperating with sensors and controllers, the flow rate and irrigation time of irrigation water can be automatically controlled based on factors such as soil moisture and meteorological conditions, achieving precise irrigation, improving water resource utilization efficiency, and saving irrigation water.

Agricultural machinery and equipment: In the hydraulic system of combine harvesters, solenoid valves are used to control the lifting of the cutting table, drive the straw crushing device, etc., to achieve automated operation of agricultural machinery and improve agricultural production efficiency.

Environmental protection field

Wastewater treatment: In the aeration system of wastewater treatment plants, solenoid valves can control the flow of air, regulate the growth environment of microorganisms in the aeration tank, and improve the effectiveness of wastewater treatment. In the process of sludge treatment, solenoid valves are used to control the flow rate in the sludge conveying pipeline, achieving stable treatment and disposal of sludge.

Waste gas treatment: In industrial waste gas treatment equipment, solenoid valves are used to control the flow of waste gas and the amount of treatment agents added, ensuring that the waste gas can be treated according to the set process flow and meet environmental emission standards. For example, in desulfurization and denitrification equipment, precise control of the injection amount of chemicals can improve the removal efficiency of sulfur oxides and nitrogen oxides in exhaust gas.

4、 Summary

As a fluid control component based on electromagnetic principles, solenoid valves have the advantages of precise control, fast response, energy conservation, environmental protection, and easy maintenance, and are widely used in various industrial fields. Understanding its working principle and importance is of great significance for the correct use and maintenance of solenoid valves. With the continuous advancement of technology, the performance and reliability of solenoid valves will be further improved, providing stronger support for industrial automation and fluid control.

Prev:Application and Advantage Analysis of Column

Next:Common faults and solutions of solenoid valves